Production

Our core skill for your benefit

Nowadays, PE film is taken for granted in the packaging of food and industrial goods. The same applies to a variety of technical application areas. However, although a piece of film may appear to be a simple product, every single sheet has many technical and economic requirements to fulfil. As one of the largest suppliers in the market, Perga offers competence, experience and the highest quality workmanship.

With state of the art extrusion equipment, we achieve maximum efficiency and sustainability. We produce tubular, semi-tubular, flat and gusseted films – as well as coextruded films.

Joscha Jost • Director Operations

We manufacture

at the highest level

Founded in 1970, Perga GmbH is now one of the leading manufacturers of mono and coextruded films, and packaging based on PE-HD, PE-LD and other polyethylenes. Our company’s continuing success is made possible through our creativity, reliability and a highly developed sense of the need for quality. We also have a good working relationship with our customers and suppliers based on a genuine sense of partnership. Furthermore, our success is down to our many dedicated staff, who manufacture precisely those products that our customers need on a daily basis.

- Competent and experienced staff

- Detailed planning up to and including delivery

- Hygienic production

- Use of advanced machining centres

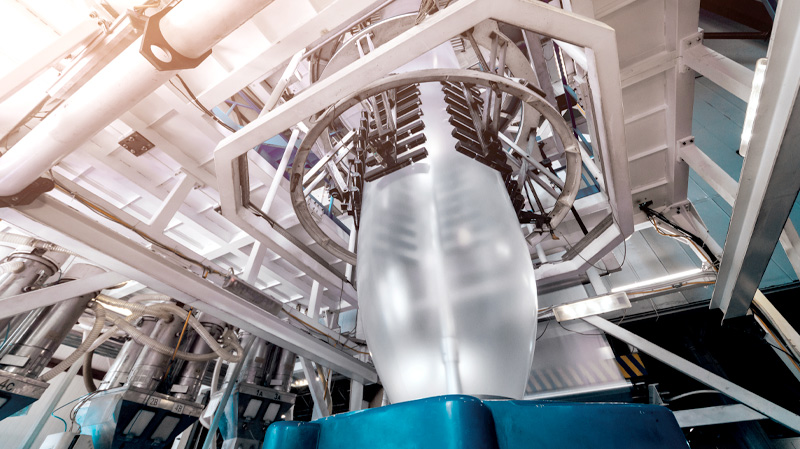

Extrusion

Our core skill

We use advanced equipment to produce tubular, semi-tubular and flat films, as well as coextruded films. As it is discharged, the molten tube is stretched extremely thinly, both longitudinally and laterally. This is achieved by blowing air in centrally, which not only stretches the tube mechanically, but also cools it and therefore fixes it in that form.

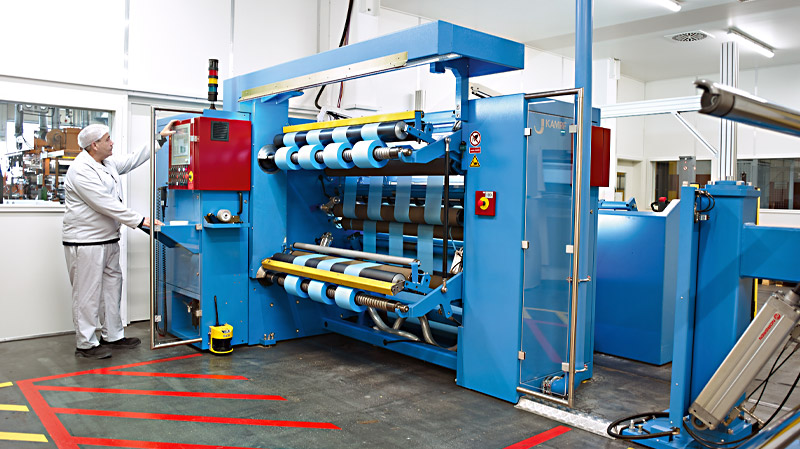

Printing

Looks matter

With our eight-colour flexographic printing presses, which are also suitable for smaller batch sizes, we print your films using the latest technology. A brilliant printed image makes you stand out from your competitors and creates a memorable impression of superior quality.

Series production

Special or standard

Competent and experienced employees produce high and low volume series for our customers, based on detailed planning of the workflows up to and including delivery. By keeping the working area clean with airlocks and other measures, we are able to offer certified hygiene with our allfolin® products. A well-assorted standard range guarantees supply to our customers, as products are available straight from the warehouse.

Thanks to over 50 years’ experience in the extrusion of PE-HD films, we can also manufacture extremely thin films which still retain their physical characteristics.

Joachim Michenfelder • Development manager

Innovation, high tech and development

A solution for everything

Conservative and established processes are a thing of the past. As the market leader for PE-HD films, we are more committed than others to flexible working processes and methods. The working environment is changing increasingly, as is the way in which companies create products and services to benefit their customers. For this reason, our engineers are always developing new and more efficient solutions to meet the challenges our customers set us.

- Solutions for all requirements from our development department

- Flat hierarchies

- Highly motivated development engineers

- Over 50 years’ experience of extrusion and processing of films

- Effective working processes